Abstract As a lightweight, high-performance alternative to traditional steel cylinder barrels, aluminum cylinder barrels have gained widespread adoption in hydraulic and pneumatic systems, driven by the global trend toward equipment miniaturization, energy efficiency, and corrosion resistance. This paper comprehensively analyzes the core mechanical and chemical advantages of aluminum cylinder barrels, elaborates on their key manufacturing processes from material selection to surface finishing, outlines typical application scenarios across multiple industrial sectors, and establishes a systematic selection guideline based on working pressure, environmental conditions, and performance requirements. The content provides a technical reference for engineers, manufacturers, and procurement professionals involved in the design and application of hydraulic/pneumatic components.

1. Introduction

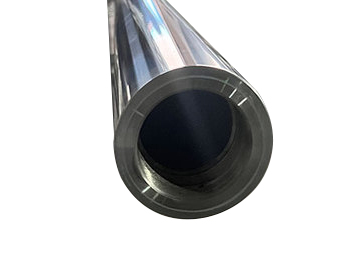

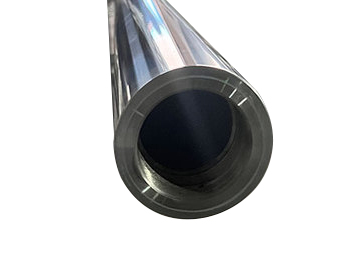

Cylinder barrels serve as the foundational structural components of hydraulic and pneumatic actuators, providing a sealed chamber for piston reciprocation and bearing system pressure loads. Traditional cylinder barrels, predominantly fabricated from carbon steel or alloy steel, exhibit high structural strength but suffer from inherent drawbacks including heavy weight, poor corrosion resistance, and high energy consumption during operation.

Aluminum cylinder barrels, manufactured from high-strength aluminum alloys, address these limitations by combining lightweight characteristics with satisfactory mechanical properties. Advances in aluminum alloy metallurgy and surface treatment technologies have further expanded their application scope, making them a preferred choice in industries such as industrial automation, new energy vehicles, aerospace, and medical equipment. This paper systematically dissects the technical attributes of aluminum cylinder barrels to guide their rational application in engineering practice.

2. Core Advantages of Aluminum Cylinder Barrels

The superior performance of aluminum cylinder barrels stems from the intrinsic properties of aluminum alloys, which offer distinct advantages over steel counterparts in specific application scenarios:

2.1 High Specific Strength and Lightweight Performance

Aluminum has a density of approximately 2.7 g/cm³, only one-third that of carbon steel (7.85 g/cm³). High-strength aluminum alloys such as 6061-T6 and 7075-T6 achieve a specific strength (strength-to-weight ratio) comparable to or even higher than low-carbon steel. The use of aluminum cylinder barrels can reduce the overall weight of hydraulic/pneumatic actuators by 40–60%, directly lowering the energy consumption of mobile equipment (e.g., aerial work platforms, agricultural machinery) and reducing the load on mounting structures in stationary systems.

2.2 Excellent Corrosion Resistance

Aluminum forms a dense, self-healing oxide film (Al₂O₃) on its surface when exposed to air. This passive film acts as a protective barrier against corrosive media such as moisture, industrial gases, and mild chemicals. Unlike steel cylinder barrels that require frequent anti-rust coating, aluminum cylinder barrels can operate stably in humid or mildly corrosive environments without additional surface treatment. For harsh corrosive conditions, surface modification processes (e.g., anodizing) can further enhance their corrosion resistance.

2.3 Superior Thermal Conductivity

The thermal conductivity of aluminum is about 4 times that of steel. Aluminum cylinder barrels can efficiently dissipate heat generated by hydraulic fluid friction and system pressure loss, preventing excessive temperature rise in the cylinder chamber. This characteristic is critical for high-frequency operation scenarios (e.g., stamping machine actuators, robotic arm cylinders), as it maintains the viscosity and lubricity of hydraulic fluid, reduces seal wear, and improves system operational stability.

2.4 Excellent Machinability and Formability

Aluminum alloys have lower hardness and better ductility than steel, enabling precision machining processes such as deep hole boring, honing, and thread cutting with higher efficiency and lower tool wear. Aluminum cylinder barrels can be fabricated into complex shapes (e.g., integrated flanges, stepped inner bores) through extrusion, forging, or welding, meeting customized design requirements for special equipment. Additionally, the near-net-shape forming capability of aluminum alloys minimizes material waste and reduces manufacturing costs.

2.5 Low Friction Coefficient

After precision honing and surface treatment, the inner wall of aluminum cylinder barrels exhibits a low friction coefficient. When paired with compatible sealing materials (e.g., polyurethane, polytetrafluoroethylene), it reduces the frictional resistance between the piston seal and cylinder wall, enabling smoother piston movement and higher control precision. This advantage makes aluminum cylinder barrels ideal for applications requiring low-speed, stable motion, such as medical equipment actuators and precision measurement devices.

3. Key Manufacturing Processes of Aluminum Cylinder Barrels

The performance of aluminum cylinder barrels is closely linked to manufacturing processes, which consist of four core stages: material selection, forming, precision machining, and surface treatment.

3.1 Material Selection

The choice of aluminum alloy grade directly determines the mechanical properties and application scope of cylinder barrels. Common grades and their characteristics are as follows:

- 6061-T6 Aluminum Alloy: The most widely used grade, featuring balanced strength, corrosion resistance, and machinability. It is suitable for medium-load hydraulic/pneumatic cylinders in industrial automation, automotive, and general machinery sectors, with a tensile strength of approximately 310 MPa and yield strength of 276 MPa.

- 7075-T6 Aluminum Alloy: A high-strength aluminum alloy with a tensile strength of up to 572 MPa, comparable to low-carbon steel. It is ideal for heavy-load cylinder barrels in aerospace and high-pressure hydraulic systems, but requires additional surface treatment due to its relatively low corrosion resistance.

- 5083-H321 Aluminum Alloy: A marine-grade aluminum alloy with excellent corrosion resistance and weldability. It is suitable for cylinder barrels used in marine equipment, coastal engineering, and chemical plants, where exposure to salt spray and corrosive media is common.

3.2 Forming Processes

1. Extrusion Forming: The primary forming method for mass-produced aluminum cylinder barrels. Aluminum alloy billets are heated to 400–500°C (a plastic state) and extruded through a die to form seamless tube blanks with uniform wall thickness. This process ensures high structural integrity and dimensional consistency, with inner diameter tolerance controlled within ±0.1 mm.

2. Forging Forming: Used for high-strength, thick-walled aluminum cylinder barrels. The billet is subjected to high-pressure forging to refine the grain structure and eliminate internal defects (e.g., porosity, segregation). Forged aluminum cylinder barrels exhibit superior fatigue resistance and are suitable for heavy-load, high-pressure applications such as aerospace hydraulic actuators.

3. Welding Forming: Employed for large-diameter or special-shaped aluminum cylinder barrels. Aluminum alloy plates are rolled into cylindrical shapes and welded using TIG (Tungsten Inert Gas) or MIG (Metal Inert Gas) welding. Strict welding quality control is required to prevent weld seam leakage and structural weakness, and post-welding heat treatment is necessary to eliminate residual stress.

3.3 Precision Machining

1. Deep Hole Boring: The tube blank is processed using CNC deep hole boring machines to achieve the required inner diameter and wall thickness tolerance. For precision applications, the inner diameter tolerance is controlled within H7–H8 grade, ensuring the fit clearance between the piston and cylinder wall meets design specifications.

2. Honing: A key process to improve the surface quality of the cylinder bore. Honing uses abrasive stones to perform low-speed, high-pressure grinding on the inner wall, reducing surface roughness to Ra 0.2–0.4 μm and forming a uniform cross-hatched texture. This texture retains lubricating oil, reduces seal friction, and extends the service life of sealing components.

3. End Machining: The ends of the cylinder barrel are machined to form mounting flanges, threaded ports, or positioning surfaces. CNC machining centers ensure the perpendicularity between the end face and inner bore axis is within 0.01 mm/m, guaranteeing compatibility with cylinder end covers and hydraulic system connections.

3.4 Surface Treatment

Surface treatment is essential to enhance the wear resistance and corrosion resistance of aluminum cylinder barrels. Common processes include:

- Anodizing: The aluminum cylinder barrel is immersed in an electrolytic solution (e.g., sulfuric acid) and subjected to anodic oxidation to form a dense oxide film (5–20 μm thick) on the surface. This film significantly improves corrosion resistance and can be dyed for aesthetic or identification purposes.

- Hard Anodizing: A specialized anodizing process conducted at low temperatures, producing a hard oxide film (20–100 μm thick) with a hardness of up to HV 500. Hard anodized aluminum cylinder barrels exhibit excellent wear resistance, suitable for high-friction, high-wear scenarios without additional coating.

- Ceramic Coating: A thermal spray process that deposits a ceramic layer (e.g., Al₂O₃-TiO₂) on the cylinder bore surface. This coating offers extreme wear resistance and corrosion resistance, making it ideal for high-pressure, high-temperature hydraulic systems in harsh environments.

4. Typical Application Scenarios of Aluminum Cylinder Barrels

Aluminum cylinder barrels are widely used in various industrial sectors due to their lightweight and corrosion-resistant properties, with typical applications as follows:

4.1 Industrial Automation Equipment

In automated production lines, aluminum cylinder barrels are integrated into lightweight pneumatic cylinders and medium-load hydraulic cylinders for workpiece clamping, material handling, and assembly operations. Their lightweight design reduces the inertia of moving parts, enabling faster response speeds and higher positioning accuracy. For example, in electronic component assembly lines, aluminum cylinder barrels are used in pick-and-place robots to achieve high-speed, stable motion with a positioning accuracy of ±0.02 mm.

4.2 New Energy Vehicles and Automotive Industry

Aluminum cylinder barrels are increasingly adopted in automotive hydraulic systems, including brake cylinders, clutch cylinders, and active suspension actuators. In electric vehicles (EVs), the lightweight advantage of aluminum cylinder barrels helps reduce vehicle curb weight, extending driving range by 3–5%. Additionally, their corrosion resistance ensures long-term reliability in the harsh under-vehicle environment, reducing maintenance costs.

4.3 Aerospace and Aviation Equipment

The aerospace industry has strict requirements for lightweight components, making aluminum cylinder barrels an ideal choice for aircraft hydraulic systems, satellite attitude control actuators, and unmanned aerial vehicle (UAV) landing gear cylinders. High-strength 7075-T6 aluminum alloy cylinder barrels can withstand high pressure (up to 31.5 MPa) and extreme temperature fluctuations, while their lightweight design reduces aircraft fuel consumption by 1–2% per 100 kg of weight reduction.

4.4 Medical Equipment

Precision aluminum cylinder barrels are used in medical devices such as surgical robots, patient lifts, and diagnostic equipment. Their low friction coefficient enables smooth, low-noise motion, critical for surgical procedures requiring high precision. Additionally, aluminum’s non-toxicity and corrosion resistance meet the strict hygiene standards of the medical industry, and electropolished aluminum cylinder barrels can be easily sterilized using autoclaving or ethylene oxide.

4.5 Marine and Coastal Engineering

Marine-grade 5083 aluminum alloy cylinder barrels are used in ship hydraulic systems, offshore platform actuators, and coastal monitoring equipment. Their excellent corrosion resistance allows them to operate stably in high-salt, high-humidity environments, eliminating the need for frequent maintenance and replacement. For example, in offshore wind turbine pitch control systems, aluminum cylinder barrels provide reliable linear actuation for 20+ years without corrosion failure.

5. Systematic Selection Guidelines for Aluminum Cylinder Barrels

Selecting the optimal aluminum cylinder barrel requires comprehensive consideration of working conditions, performance requirements, and compatibility with system components. The following guidelines should be followed:

5.1 Match Material Grade to Load and Pressure Requirements

- Low-to-medium load, low-pressure applications (≤16 MPa): Choose 6061-T6 aluminum alloy for its balanced cost, strength, and corrosion resistance, suitable for general industrial pneumatic and hydraulic systems.

- Heavy-load, high-pressure applications (16–31.5 MPa): Select 7075-T6 aluminum alloy for its high tensile strength, and complement it with hard anodizing or ceramic coating to enhance corrosion resistance.

- Corrosive environments (e.g., marine, chemical plants): Adopt 5083-H321 marine-grade aluminum alloy for its superior corrosion resistance, eliminating the need for additional surface treatment in most cases.

5.2 Select Surface Treatment Based on Working Environment

- Mild indoor environments: Standard anodizing (5–10 μm film thickness) is sufficient to prevent corrosion.

- High-wear scenarios (e.g., high-frequency reciprocating motion): Hard anodizing or ceramic coating is required to enhance surface hardness and wear resistance.

- Harsh corrosive environments (e.g., salt spray, chemical vapor): Thick anodizing (15–20 μm) or ceramic coating is recommended to ensure long-term corrosion protection.

5.3 Ensure Compatibility with Sealing Components

The surface texture and material of aluminum cylinder barrels must be compatible with sealing materials to avoid seal wear and leakage:

- For polyurethane (PU) seals, a honed surface with Ra 0.2–0.3 μm is ideal, as it reduces friction and extends seal life.

- For polytetrafluoroethylene (PTFE) seals, a slightly rougher surface (Ra 0.3–0.4 μm) helps retain lubricating oil and prevent seal slippage.

- Avoid using nitrile rubber (NBR) seals in long-term applications with aluminum cylinder barrels, as NBR may react with aluminum and cause seal swelling.

5.4 Consider Installation Space and Maintenance Requirements

- Limited installation space: Choose aluminum cylinder barrels with threaded end covers or integrated structures to reduce overall dimensions.

- Frequent maintenance scenarios: Select cylinder barrels with flange connections for easy disassembly and replacement of seals and guide components.

- Low-maintenance scenarios (e.g., offshore equipment): Opt for welded end cover structures with high sealing performance to reduce maintenance frequency.

5.5 Evaluate Cost-Effectiveness

Aluminum cylinder barrels have a higher initial cost than steel cylinder barrels, but their lightweight and low-maintenance characteristics reduce long-term operational costs. Conduct a life-cycle cost analysis: for mobile equipment and large-scale industrial systems, the energy savings and maintenance cost reductions of aluminum cylinder barrels often offset their higher initial investment within 1–2 years of operation."