Design Key Points And Functional Analysis Of Hydraulic Cylinder Blocks: Comprehensive Mastery Of Core Structures And Selection Principles

Release time:2025-12-08

Visits:184

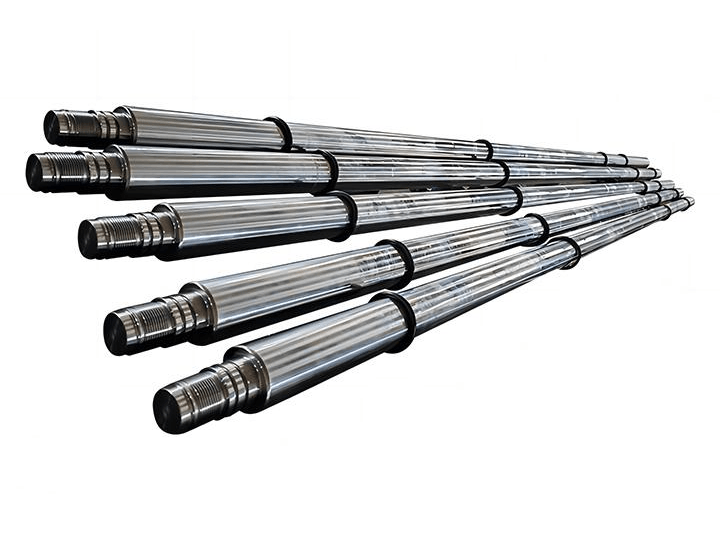

As a core executive component in hydraulic systems, hydraulic cylinder blocks undertake the dual mission of energy conversion and mechanical action output. This article systematically interprets their design characteristics, manufacturing specifications, and selection strategies to help users deeply understand the working principle and application value of this critical component.

1. Analysis of Core Structures of Cylinder Blocks

1.1 Rigid Load-Bearing Structure

Hydraulic cylinder blocks adopt cylindrical barrels as main pressure-bearing components, with precision-machined interiors achieving mirror-level surface finish to effectively reduce piston movement friction. Both ends are equipped with high-precision end caps, achieve a sealed connection through flange, thread, or welding connections, capable of withstanding high-pressure environments up to 31.5MPa.

1.2 Intelligent Sealing System

The multi-stage sealing system includes dynamic piston seals and static end cap seals, combined sealing rings are used (polyurethane/fluororubber) with dust-proof ring matching schemes. The new stepped sealing technology can automatically compensate for wear gaps, increasing service life by 30% compared to traditional structures.

2. Key Material Technical Parameters

| Material Type | Tensile Strength | Applicable Pressure | Typical Application Scenarios |

|---------------|------------------|---------------------|-------------------------------|

| Alloy Steel | 600-900MPa | 25-31.5MPa | Construction Machinery Hydraulic Systems |

| Forged Aluminum Alloy | 300-500MPa | 16-25MPa | Aerospace Hydraulic Devices |

| Composite Ceramic Coating | ≥1200HV | Special Working Conditions | Highly Corrosive Industrial Environments |

3. Engineering Design Criteria

3.1 Dynamic Balance Design

In view of reciprocating motion characteristics, adjustable flow buffering devices are configured to optimize speed curves through stepped pressure reduction via damping holes. Intelligent exhaust systems can automatically discharge oil bubbles, ensuring motion stability error < 0.02mm/m.

3.2 Modular Installation Interfaces

Provide standardized installation schemes including flange-type, trunnion-type, and base-type, cooperate ISO 6020/6022 standard dimension system to support quick replacement and maintenance. Heavy-duty equipment adopts enhanced key connection structures, increasing impact resistance by 45%.

4. Full-Scenario Adaptation Solutions

- Industrial Manufacturing Field: Injection molding machines equipped with multi-stage telescopic cylinder blocks, achieving stroke accuracy of ±0.05mm

- Construction Engineering Machinery: Excavator boom hydraulic cylinders three-layer chrome plating process, with wear resistance coefficient > 0.8

- Vehicle Transportation Systems: Hydro-pneumatic suspensions configured with bidirectional buffering cylinder blocks, achieving vibration absorption efficiency > 92%

5. Technical Specifications for Selection

5.1 Working Condition Matching Principles

Calculate thrust requirements based on load characteristics: F=π(D²-d²)P/4 (D: piston diameter, d: rod diameter, P: working pressure). For high-speed scenarios, it is recommended to select piston rod diameter ratio ≥0.7, while for low-speed heavy-load applications, adopt rod diameter ratio ≤0.5 design.

5.2 Reliability Verification Standards

Strictly implement 5 million fatigue tests, requiring:

- Deformation < 0.1%L (L is stroke length)

- Seal leakage < 0.5ml/h

- Surface hardness reduction < 10%

5.3 Environmental Adaptability Design

Adopt surface strengthening technologies for special working conditions:

- Hard chrome plating layer thickness 50-150μm, microhardness ≥800HV

- Plasma-sprayed WC-Co coating, friction coefficient ≤0.15

- PTFE impregnation treatment extends temperature resistance range to -50℃~260℃

From the above systematic analysis, it can be seen that modern hydraulic cylinder block design integrates multi-disciplinary technologies such as materials engineering, precision manufacturing, and intelligent control. Reasonable selection of cylinder block specifications and strict implementation of maintenance standards can improve the overall efficiency of hydraulic systems by more than 40% and extend equipment operational life by 3-5 maintenance cycles.