Benefits Of Using Stainless Steel Hollow Rods

Release time:2026-01-26

Visits:26

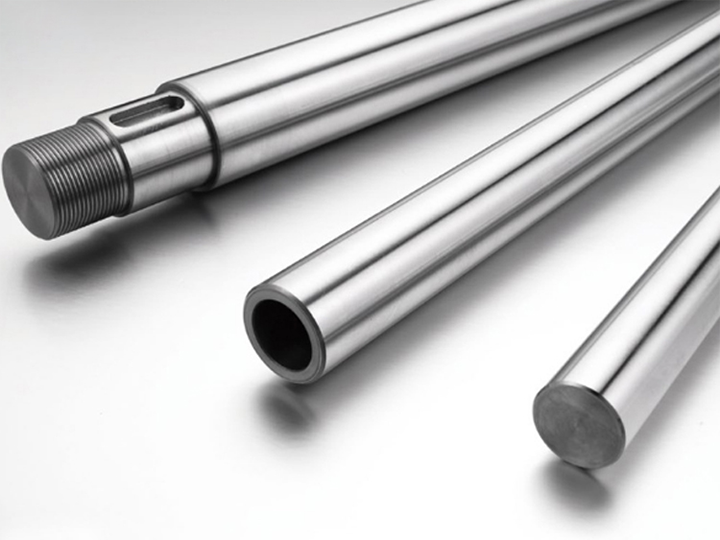

In industrial engineering, material selection is a pivotal determinant of operational efficiency, service life, and cost optimization. Stainless steel hollow rods have established themselves as a premium solution across diverse sectors, owing to their synergistic combination of mechanical performance and material efficiency. Whether deployed in high-pressure hydraulic systems or load-bearing structural frameworks, these components outperform their solid counterparts in critical technical and economic metrics.

Stainless steel hollow rods are cylindrical stainless steel components characterized by a central hollow cavity. Distinguished from solid piston rods, their hollow architecture delivers a superior strength-to-weight ratio—an attribute that renders them indispensable for applications demanding both structural integrity and lightweight design. They are widely integrated into manufacturing, civil engineering, and automotive systems, leveraging their adaptability and resistance to harsh operating conditions.

1. Corrosion Resistance

Stainless steel inherently exhibits robust corrosion resistance, a non-negotiable property for components operating in aggressive industrial environments (e.g., humid, chemical-laden, or saline settings). This intrinsic characteristic extends service longevity and minimizes lifecycle maintenance costs, reducing unplanned downtime for system overhauls.

2. High Strength and Durability

Despite their hollow configuration, these rods maintain exceptional tensile strength and fatigue resistance, enabling them to withstand extreme mechanical stress and cyclic loading. This performance makes them suitable for heavy-duty applications such as industrial hydraulic cylinders and structural bracing systems.

3. Weight Reduction Advantage

The hollow design achieves substantial weight reduction without compromising structural performance. This feature is critical for weight-sensitive sectors, including aerospace and automotive engineering, where reduced mass directly translates to improved energy efficiency and payload capacity.

4. Fabrication Versatility

Stainless steel hollow rods are amenable to precision machining, welding, and surface treatment processes, allowing for customization to meet application-specific dimensional and performance requirements. This versatility facilitates their integration into bespoke industrial systems and prototype development projects.

Typical Industrial Applications

- Hydraulic Systems: Core components such as excavator hydraulic cylinder piston rods and hollow piston rods rely on the rods’ high strength-to-weight ratio to ensure smooth actuation, reduce energy consumption, and withstand prolonged high-pressure operation.

- Civil Construction: Deployed in structural frameworks and load-bearing supports, these rods resist environmental degradation (e.g., atmospheric corrosion, temperature fluctuations) and heavy static/dynamic loads, contributing to the durability of infrastructure projects.

- Automotive Manufacturing: Integrated into hollow rod cylinders and compact piston rod assemblies, they support vehicle lightweighting initiatives, enhancing fuel efficiency while maintaining the mechanical reliability required for automotive powertrains and chassis systems.

- General Manufacturing: Utilized in the production of machinery components and industrial fixtures, their wear resistance and structural stability make them suitable for high-cycle, high-stress manufacturing environments.

Comparative Advantages Over Solid Piston Rods

When evaluated against solid piston rods, stainless steel hollow rods demonstrate clear technical and economic superiority:

1. Cost-Effectiveness

Reduced material consumption lowers production costs significantly, a benefit that scales exponentially in large-scale industrial projects. This cost advantage does not compromise performance, making hollow rods a cost-efficient alternative for volume applications.

2. Enhanced Operational Performance

The lightweight design reduces inertial loads on machinery and vehicles, improving response speeds, lowering energy consumption, and extending the service life of associated components (e.g., bearings, seals).

3. Design Flexibility

The hollow structure enables innovative design solutions, such as the integration of internal fluid channels or sensor wiring, expanding the functional scope of the component beyond traditional load-bearing applications.

4. Environmental Sustainability

Reduced raw material usage aligns with sustainable manufacturing principles, minimizing resource depletion and carbon footprint throughout the product lifecycle.

Key Selection Criteria for Stainless Steel Hollow Rods

To maximize the performance of stainless steel hollow rods in specific applications, the following factors must be prioritized:

- Stainless Steel Grade: Select grades based on corrosion resistance, tensile strength, and machinability requirements. For example, 316 stainless steel is preferred for marine or chemical environments, while 304 stainless steel suffices for general industrial applications.

- Dimensional Accuracy: Ensure precise matching of outer diameter, inner diameter, and length to system specifications, as dimensional deviations can compromise assembly integrity and operational safety.

- Surface Finish: Choose surface treatments (e.g., polishing, passivation, hard chrome plating) based on application needs—polished finishes reduce friction in dynamic systems, while passivation enhances corrosion resistance.

- Supplier Qualification: Partner with certified manufacturers to guarantee compliance with industry standards (e.g., ASTM, ISO). Rigorous quality control ensures consistent material properties and dimensional tolerances.