Selecting an optimal hollow piston cylinder for industrial applications presents a critical engineering decision, as the component’s performance directly impacts operational efficiency, safety, and lifecycle cost. Hollow piston cylinders—also referred to as hollow plunger hydraulic cylinders—are specialized hydraulic actuation devices characterized by a central through-bore, enabling rod or cable penetration for tensioning, pulling, or through-hole applications. Widely deployed across construction, automotive, industrial, and marine sectors for tasks such as precision lifting, structural tensioning, and component manipulation, these cylinders demand rigorous evaluation of technical parameters to align with application requirements. This guide outlines key design classifications, critical selection criteria, industrial use cases, and maintenance best practices to facilitate informed decision-making.

Core Design Classifications of Hollow Piston Cylinders

Hollow piston cylinders are differentiated by actuation mode and application-specific design optimizations, each tailored to distinct operational demands:

1. Single-Acting Hollow Piston Cylinders

Single-acting cylinders generate extension force via hydraulic pressure and rely on external loads, mechanical springs (e.g., nitrogen-charged or coil springs), or gravity for retraction. Engineered for simplicity and cost-effectiveness, they feature a compact footprint and reduced hydraulic circuit complexity. Ideal for unidirectional tasks such as vertical lifting, bolt tensioning, or pushing applications, these cylinders are commonly specified in scenarios where retraction force requirements are minimal. Key technical attributes include spring fatigue resistance and pressure retention capabilities (typically 10,000–30,000 PSI).

2. Double-Acting Hollow Piston Cylinders

Double-acting cylinders deliver bidirectional force control, with both extension and retraction powered by hydraulic pressure. This design enables precise speed and position regulation, making them suitable for dynamic applications requiring repeatable motion (e.g., machinery alignment, precision pressing, or automated assembly). Equipped with dual hydraulic ports and sealed piston assemblies, they offer enhanced operational flexibility and load control. Critical specifications include symmetric force output (extension vs. retraction) and minimal internal leakage (compliant with ISO 4406 cleanliness standards).

3. Hollow Piston Lifting Cylinders

Specialized for heavy-load lifting and load-holding applications, these cylinders integrate high-strength structural features such as reinforced cylinder barrels, anti-slip piston heads, and pressure-retaining valves (e.g., check valves or relief valves). Designed to accommodate static and dynamic loads, they are certified for use in construction, bridge maintenance, and heavy machinery operations. Key design optimizations include high load-bearing capacity (up to 1,000+ tons), corrosion-resistant coatings, and compatibility with load-monitoring systems.

Critical Selection Criteria for Optimal Performance

The selection of a hollow piston cylinder requires rigorous evaluation of technical parameters to ensure compatibility with system requirements and operational safety:

1. Load Capacity & Safety Factor

Load capacity—defined as the maximum force the cylinder can safely exert—must account for both static and dynamic loads (e.g., shock loads, inertial forces). Industry standards (e.g., ASME B30.1, ISO 14726) mandate a minimum safety factor of 1.5–2.0, meaning the cylinder’s rated load should exceed the maximum expected application load by 50–100%. For tensioning applications, additional consideration of tensile strength and fatigue resistance is critical to prevent structural failure under cyclic loading.

2. Stroke Length & Dimensional Compatibility

Stroke length refers to the maximum linear displacement of the piston, which must align with the application’s required range of motion. Engineers must distinguish between effective stroke (usable displacement) and retracted length (compact storage dimension) to ensure fit within system envelopes. Dimensional compatibility also includes cylinder outer diameter, piston rod diameter, and through-bore size—all of which must integrate with existing machinery, fixtures, or cables.

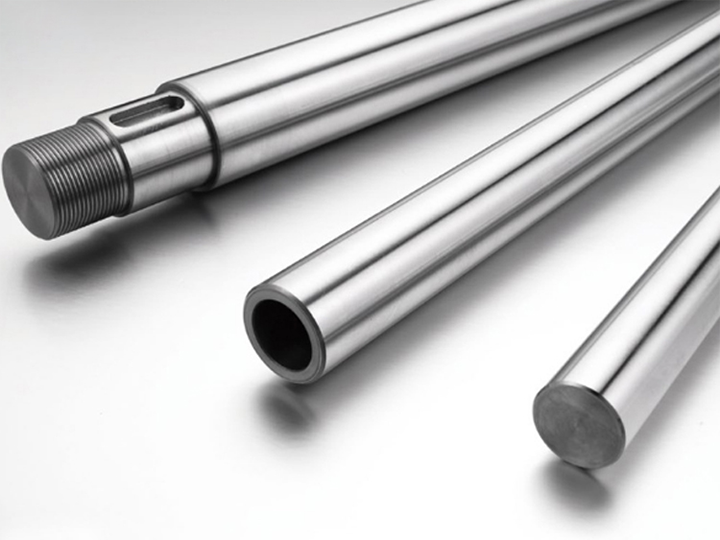

3. Material Selection & Environmental Resistance

Cylinder construction materials are selected based on load requirements, environmental conditions, and corrosion exposure:

- High-Strength Steel: Alloy steels (e.g., 4140, 4340) or stainless steel (316L, 17-4 PH) are preferred for heavy-duty applications, offering exceptional tensile strength (800–1,500 MPa) and resistance to mechanical wear.

- Aluminum Alloys: 6061-T6 or 7075-T6 aluminum is utilized for lightweight applications (e.g., portable equipment, aerospace components), providing corrosion resistance and reduced system inertia.

- Coatings & Treatments: Hard chrome plating, zinc-nickel coating, or ceramic finishes enhance wear resistance and protect against harsh environments (e.g., saltwater, chemical exposure).

4. Hydraulic Connection & System Compatibility

Connection types must align with the hydraulic system’s port specifications, including thread standards (e.g., BSPP, NPT, SAE J1926) and flange configurations (SAE J518). Quick-connect fittings are suitable for portable applications, while threaded or flange connections offer enhanced leak resistance for high-pressure systems. Compatibility with hydraulic fluids (e.g., mineral oil, synthetic esters, water-glycol) is also critical to prevent seal degradation and ensure long-term performance.

5. Operating Pressure & Temperature Range

The cylinder’s rated operating pressure must match or exceed the hydraulic system’s maximum working pressure (typically 3,000–10,000 PSI for industrial applications). Temperature tolerance is equally important—cylinders must maintain structural integrity and seal performance within the application’s operating temperature range (-40°C to 120°C for standard designs, with high-temperature variants available for extreme environments).

Industrial Applications & Technical Use Cases

Hollow piston cylinders are engineered to address specialized challenges across key sectors:

- Construction & Civil Engineering: Prestressing concrete cables, lifting precast components, tensioning bridge stay cables, and aligning heavy structural steel.

- Automotive & Aerospace: Press-fit bearing installation, gear extraction in powertrain maintenance, aircraft component assembly, and lightweight lifting for vehicle diagnostics.

- Industrial Manufacturing: Structural load testing (per ASTM E4), precision machinery alignment, bolt tensioning in heavy equipment, and automated assembly line actuation.

- Marine & Offshore: Mooring cable tensioning, offshore platform equipment lifting, ship hull maintenance, and corrosion-resistant tensioning for marine structures.

Maintenance & Safety Best Practices

To ensure operational reliability and extend service life, adherence to rigorous maintenance and safety protocols is essential:

- Routine Inspection & Non-Destructive Testing (NDT): Conduct periodic visual inspections for leaks, corrosion, or structural damage. Utilize ultrasonic testing (UT) or magnetic particle inspection (MPI) to detect internal cracks or material fatigue.

- Fluid Management: Maintain hydraulic fluid cleanliness (per ISO 4406 Class 16/13) and replace fluids at manufacturer-recommended intervals. Monitor fluid temperature and viscosity to prevent seal degradation.

- Storage & Handling: Store cylinders in a clean, dry environment (5–30°C, 40–60% humidity) per ISO 9001 storage standards. Protect through-bores and hydraulic ports with caps to prevent contamination.

- Accessory Compatibility: Use only OEM-certified accessories (e.g., pressure gauges, quick-connect fittings, load cells) to avoid system incompatibility and safety hazards.

- Compliance with Standards: Adhere to industry-specific regulations (e.g., API 7K for oilfield applications, ASME B30.1 for lifting equipment) and manufacturer guidelines for operation, pressure limits, and maintenance intervals.