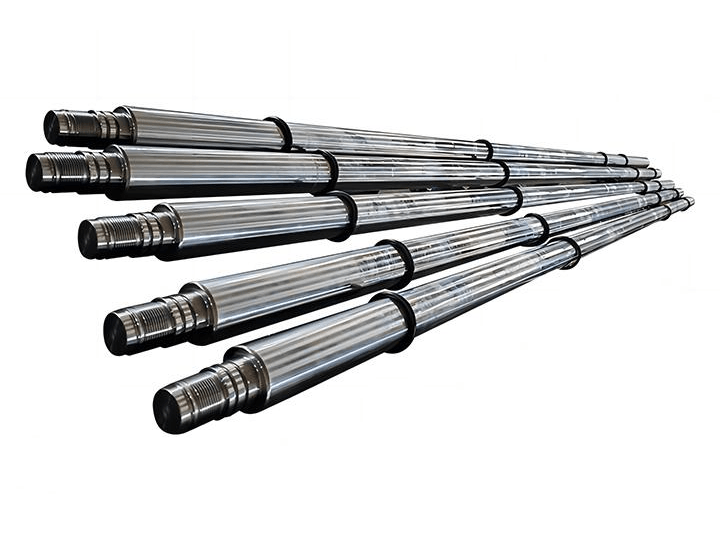

In hydraulic systems, the piston rod serves as a critical load-bearing and force-transmitting component, whose mechanical performance directly dictates system efficiency, reliability, and service life. Among the materials widely adopted for high-performance piston rods, CK45 carbon steel—when enhanced with hard chrome plating (HCP)—stands out as a cost-effective and technically robust solution. This article systematically explores the material properties, surface treatment advantages, industrial applications, manufacturing processes, and technical merits of CK45 carbon steel hard chrome plated

hydraulic cylinder piston rods, providing engineering insights for material selection and system optimization.

1. Material Overview: CK45 Carbon Steel

CK45 is a medium-carbon structural steel compliant with DIN EN 10083-2 and GB/T 3077 standards, renowned for its balanced mechanical properties and processability, making it the preferred substrate for hydraulic piston rods.

1.1 Chemical Composition (Wt%)

- Carbon (C): 0.42–0.50% (core element for strength regulation)

- Silicon (Si): 0.17–0.37%

- Manganese (Mn): 0.50–0.80%

- Phosphorus (P): ≤0.035%

- Sulfur (S): ≤0.035%

- Iron (Fe): Balance

1.2 Key Mechanical Properties (After Quenching & Tempering, QT 600-800)

- Tensile Strength (σb): 600–800 MPa

- Yield Strength (σs): ≥355 MPa

- Elongation (δ5): ≥16%

- Hardness (HB): 179–229

- Impact Toughness (αk): ≥47 J/cm² (20°C)

1.3 Material Advantages for Piston Rods

- Optimal Strength-Toughness Balance: The medium carbon content enables CK45 to achieve high tensile strength and moderate ductility after heat treatment, resisting cyclic fatigue under repeated hydraulic loading.

- Excellent Machinability: Compatible with precision turning, grinding, and threading processes, ensuring tight dimensional tolerances (ISO 286-2 h7) and surface finish requirements.

- Cost-Effectiveness: Offers superior performance compared to low-carbon steels (e.g., Q235) while remaining more economical than alloy steels (e.g., 4140, 4340), reducing total ownership costs.

- Heat Treatment Adaptability: Quenching and tempering (QT) or induction hardening can further enhance surface hardness (up to HRC 50–55) without compromising core toughness.

2. Hard Chrome Plating (HCP) Enhancement

Hard chrome plating is a critical surface modification process for CK45 piston rods, addressing the substrate’s inherent limitations (e.g., poor corrosion and wear resistance) and elevating overall performance.

2.1 Plating Process Specifications

- Plating Thickness: 0.02–0.15 mm (customizable based on application requirements; typical industrial standard: 0.05–0.10 mm)

- Plating Hardness: HRC 60–70 (via electrolytic deposition of chromium, forming a dense, wear-resistant chromium carbide layer)

- Surface Finish: Ra 0.05–0.2 μm (after grinding and polishing, ensuring compatibility with hydraulic seals)

- Process Standards: Complies with ASTM B117 (salt spray corrosion resistance) and ASTM B651 (chrome plating for engineering components)

2.2 Core Benefits of Hard Chrome Plating

- Superior Corrosion Resistance: The chrome layer acts as a barrier against moisture, hydraulic fluids, and harsh industrial environments (e.g., humidity, chemicals), passing 200+ hours of neutral salt spray testing (ASTM B117).

- Enhanced Wear Resistance: The high-hardness chrome layer reduces abrasive and adhesive wear caused by seal contact, contaminant particles, and repeated linear motion, extending piston rod service life by 3–5x compared to unplated rods.

- Reduced Friction: The ultra-smooth surface minimizes frictional resistance between the rod and seals (e.g., polyurethane, nitrile rubber), improving hydraulic system efficiency and reducing energy consumption.

- Seal Protection: Prevents seal damage from surface irregularities, extending seal lifespan and reducing hydraulic leakage risks.

3. Key Industrial Applications

CK45 carbon steel hard chrome plated piston rods are widely deployed in hydraulic systems across high-demand sectors, leveraging their balanced performance and cost-effectiveness:

3.1 Industrial Machinery

- Hydraulic cylinders for injection molding machines, hydraulic presses, and metal forming equipment: Withstands high pressure (up to 31.5 MPa) and cyclic loading, ensuring precise motion control.

- Conveyor systems and material handling equipment: Resists wear from dust and debris, maintaining operational stability in harsh factory environments.

3.2 Construction & Heavy Equipment

- Hydraulic cylinders for excavators, bulldozers, and cranes: Endures heavy loads, impact forces, and outdoor corrosion (e.g., rain, soil moisture), ensuring reliable operation in construction sites.

- Bridge and structural engineering: Used in hydraulic jacks and tensioning systems, leveraging high strength and corrosion resistance for long-term service.

3.3 Automotive & Transportation

- Shock absorber piston rods and hydraulic suspension components: Balances strength and ductility, absorbing road vibrations and ensuring vehicle stability.

- Commercial vehicle hydraulic systems (trucks, buses): Resists wear from frequent braking and load changes, reducing maintenance downtime.

3.4 General Hydraulic Systems

- Pumps, valves, and actuators in industrial automation: Ensures tight seal compatibility and low friction, optimizing system responsiveness and efficiency.

- Marine hydraulic systems: Withstands saltwater corrosion (when combined with additional corrosion inhibitors), suitable for shipboard equipment.

4. Technical Advantages Over Alternative Solutions

Compared to piston rods made from alloy steels (4140, 17-4 PH) or stainless steel (304, 316L), CK45 hard chrome plated rods offer distinct competitive edges:

| Advantage Category | CK45 Hard Chrome Plated | Alternative Materials |

|--------------------------------|-------------------------------------------------------|---------------------------------------------------|

| Cost-Effectiveness | 30–50% lower material and processing costs than alloy steels | Higher raw material costs (alloy steels/stainless steel) |

| Strength-Toughness Balance | Optimal for medium-high load applications (≤31.5 MPa) | Alloy steels offer higher strength but at higher cost; stainless steel has lower tensile strength |

| Wear/Corrosion Resistance | Hard chrome layer provides comparable performance to stainless steel | Stainless steel has inherent corrosion resistance but lower wear resistance without plating |

| Machinability | Excellent, enabling tight tolerances and complex geometries | Stainless steel has poor machinability; alloy steels require specialized tooling |

| Seal Compatibility | Ultra-smooth chrome surface minimizes seal wear | Unplated alloy steels/stainless steel may cause premature seal failure |

5. Manufacturing Process & Quality Control

The production of CK45 hard chrome plated piston rods requires strict process control to ensure dimensional accuracy and performance consistency:

5.1 Core Manufacturing Steps

1. Material Selection: High-quality CK45 steel bars (hot-rolled or cold-drawn) with consistent chemical composition and no internal defects (verified via ultrasonic testing).

2. Precision Machining:

- Turning and grinding to achieve target outer diameter (OD) and straightness (≤0.1 mm/m).

- Surface preparation (Ra 0.8–1.6 μm) for plating adhesion.

3. Heat Treatment: Quenching (820–860°C) and tempering (550–650°C) to achieve QT 600-800 mechanical properties.

4. Chrome Plating:

- Pre-treatment: Degreasing, (pickling), and activation to remove surface contaminants and oxide layers.

- Electrolytic plating: Chromium deposition in a chromic acid bath, controlled via current density (20–60 A/dm²) and temperature (50–60°C).

- Post-treatment: Rinse, passivation, and grinding/polishing to achieve final surface finish (Ra 0.05–0.2 μm).

5. Quality Control & Inspection:

- Dimensional inspection: CMM (Coordinate Measuring Machine) for OD tolerance (h7) and straightness.

- Non-Destructive Testing (NDT): Ultrasonic testing (UT) for internal defects, magnetic particle inspection (MPI) for surface cracks.

- Plating quality: Thickness measurement (eddy current testing), hardness testing (Vickers microhardness), and adhesion testing (ASTM D3359 tape test).

- Corrosion resistance: Salt spray testing (ASTM B117) for 200+ hours.

5.2 Key Quality Standards

- Dimensional Tolerance: ISO 286-2 h7 (outer diameter)

- Surface Finish: Ra 0.05–0.2 μm

- Plating Thickness: ±0.01 mm

- Straightness: ≤0.1 mm/m

- Corrosion Resistance: ≥200 hours salt spray (ASTM B117)